hardness test plastics|hardness of plastics chart : bespoke Several verifiable hardness scales have been developed to test and analyze hardness. They are well equipped to replicate scratching, rubbing, and wear between two . webThanks to crossplay, virtual farmers can play Farming Simulator 22 together, regardless of their preferred platform.

{plog:ftitle_list}

WEBMoodle UFRGS é um sistema de gerenciamento de aprendizagem de código aberto, livre e gratuito, que permite aos usuários baixar, modificar e distribuir cursos online. Saiba .

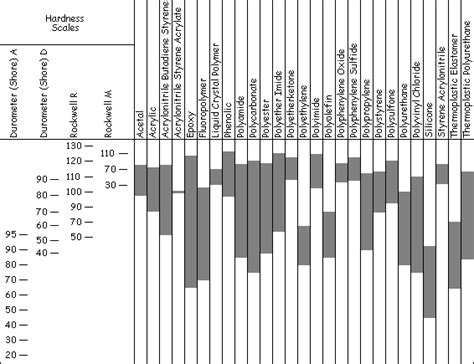

ISO 2039-2 and ASTM D785 define various Rockwell hardness scales for plastics testing. In contrast to ball indention hardness, in which the indention depth is measured under load, with the Rockwell method, the indention depth is measured at a defined preload.Standardized optical hardness testing methods include the Brinell hardness . Several verifiable hardness scales have been developed to test and analyze hardness. They are well equipped to replicate scratching, rubbing, and wear between two .DUH-210 Dynamic Ultra Micro Hardness Tester for plastics. Table 2 Specimen Information Sample name PP, HDPE, ABS/PMMA, and PS Sample geometry Rectangular solid, 20 mm × 10 mm × 3 mm Table 3 Test Conditions Instrument Plastic hardness analyzer (Dynamic Ultra Micro Hardness Tester for plastics DUH-210) Room temperature (°C) 23 ± 2 Humidity

Specific cases where Brinell hardness testing is applied: Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-The Rockwell M hardness test is not valid for plastics that are less than 0.05 inch (1.27 mm) thick. This is because the indenter can penetrate too deeply into thin materials, giving a falsely high hardness reading. Temperature Small changes in temperature can result in first and second-order phase transitions. This can alter the hardness of .

Learn how Shore D Hardness test work, its significance to determine hardness of the material as well as what are common polymers this test is used for. . For rubbers, elastomers & softer plastics, Shore Hardness is often preferred. Very soft materials can be measured using Shore A hardness. It is generally used for hard materials, like PA, PCFlexural Test - Plastics ASTM D790 and ISO 178; Flexural Test - Composites Four Point Bending ASTM D6272; Flexural Test - Composites ASTM D7264; Flexural Test - Core (4-pt flexure) ASTM D7249; Flexural Test - Facesheet Compressive Strength ASTM D5467; Fogging SAE J1756, ISO 6452, DIN 75201; Fourier Transform Infrared Analysis (FTIR) ASTM E1252 .The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.Rockwell hardness testing plastics. Used to determine the relative hardness of materials such as plastics, the Rockwell Hardness Test is a popular and non-destructive method. It uses a diamond cone or hardened steel ball deployed against the .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The hardness testing of plastics is most commonly measured by the Shore (Durometer) test or Rockwell hardness test. Both methods measure the resistance of the plastic toward indentation. Both scales provide an empirical hardness value that doesn't correlate to other properties or fundamental characteristics. Shore Hardness, using either the .2 Plastics testing Content Page 2.1 Application overview - plastics 5 2.2 Molding materials and plastic products 6 2.3 Testing pipes 9 . for hardness testing, solutions for impact testing, soluti-ons for melt index determination. And for that rare occasion when we don’t have a stan-

The hardness of plastics and hard rubber can be determined using a loaded ball indenter in accordance with standard ISO 2039-1 or ISO 2039-2. Standard ISO 2039-1 describes determination of the hardness value by means of a ball indenter test.The measured indentation depth is used to calculate the surface area of the indent and subsequently the hardness. This publication provides, based on the state of standardization, an overview of the hardness testing of metals, plastics, rubber and other materials. It reports on technical developments such as the introduction of image processing in the Brinell and Vickers method, the adaptation of hardness testing machines to process-oriented testing .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . It is also suitable for a wide range of materials including metals, plastics and ceramics. The Rockwell test offers several different .D618-21 Standard Practice for Conditioning Plastics for Testing . D3045-18 Standard Practice for Heat Aging of Plastics Without Load . D1712-09(2020) Standard Practice for Resistance of Plastics to Sulfide Staining . D785-23 .In addition, creep testing and dynamic mechanical analyses of viscoelastic plastics are briefly described. The discussion covers the most commonly used tests for impact performance, various types of hardness test for plastics, the fatigue strength of viscoelastic materials, and the tension testing of elastomers and fibers.7.1 The testing area shall be smooth and free from mechani-cal defects. 7.2 Dimensions—Test specimens shall be at least 1.5 mm [1⁄ 16 in.] thick and large enough to ensure a minimum distance of3mm[1⁄ 8 in.] in any direction from the indentor point to the edge of the specimen, as well as from test point to test point. 8.

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . ductility, resistance to wear and plastic deformation, elasticity, and tendency to fracture. It also provides crucial clues about material's suitability for a .

Testlopedia - The Plastics Testing Encyclopedia; Barcol Hardness ASTM D2583; Rockwell Hardness ASTM D785, ISO 2039; Need help or have a question? +1 413 499 0983. Additional Phone Numbers. APAC +65 6805 4800. UK - Wilton +44 1642 435 788. Benelux +31 88 126 8888. Germany 0800 5855888. Switzerland +41 61 686 4800. Mexico 01 800 5468 3783.The easy to use hardness testing software supports the operator with single tests, as well as complex test tasks. Hardness testing according to current standards. Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing.

Hardness testing measures the depth of indentation of a ball into a sample. Hardness property values are then calculated using tables derived from the empirical relationship between indentation depth and hardness levels. . ASTM D785 Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials; ASTM D1415 Standard .plastics like TPE. The Shore D Scale is similar to Shore A. as it measures semi-rigid plastics. In. fact, the low end of Shore D - 0 actually overlaps with Shore A - 60. Shore D however can measure the hardness of super rigid plastics like PVC. The Rockwell scale measures hard materials: PA,PC, PS, and POM. According to material experts, this test To determine dynamic hardness, the indenter is forced under high loading rate which leads to impact or chock the test material. Thus, the indenter could be shot the tested material like a projectile onto the target surface (Low 2006; El-Ezz 2007).The test material must be permanently deformed, so the kinetic energy should be chosen to assure plastic .

rockwell hardness chart for plastics

This document specifies a hardness test method for plastics using instrumented indentation in the micro scale with one clearly defined test condition to ensure reproducibility and comparability of test results. The test method is selectively suitable for use with the following materials:This test can be used to determine the hardness of plastics with the ball indentation (ISO 2039-1) or Shore hardness (ISO 868) method.Testing is performed at room temperature and includes three measurements per sample. This Type D durometer tests the hardness of hard rubber and plastics. Test block for Type D durometers provides you the ability to develop the proper "feel". while not to be used for calibration purposes, this Test block enables you to perform a quick check for the proper operation of the durometer.

lee lead hardness tester instructions

lee lead hardness tester review

Resultado da Gif Sentando No Pau » Xvideos ON um dos melhores sites porno do brasil, diversas putarias sem custos, todas as vezes que você desejar Gif Sentando No Pau, visite nosso acervo de videos adultos.Você vai frequentemente achar novos pornos em nossa pagina inicial. Do contrário de muitos sites do .

hardness test plastics|hardness of plastics chart